roughing end mill cutter diagram

Get your content registered in a globally recognized 3rd party system. There is an increasing trend to employ SAG mills semiautogenous mills in place of secondary and tertiary crushing and primary grinding.

Endmill Selection Guide Redline Tools Redline Tools

The RPM for a l2-inch-diameter end mill machining aluminum revolves at 2400 RPM and the feed rate should be 24 inches per minute.

. Click to see the answer Q. Imagine how a CAM program might work for the lathe. Roughing End Mills.

SAG mills rod mills and ball mills are the classical pieces of grinding equipment employed in gold recovery plants. MACHINE SHOP PRACTICE S5 MECH 2015 53 17613 Helical Milling Operation Helical milling produces helical flutes or grooves on the periphery of a cylindrical or conical work piece. G71 Rough Turning Cycle Overview.

Find the cutting speed in meterminute for a step milling operation by 22mm end mill with a spindle A. The cutter selection also depends upon tooth profile and their spacing. Of and in a to was is for as on by he with s that at from his it an were are which this also be has or.

Up to 34 of the cutter diameter it doesnt matter which way you cut. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Complete Indexable End Mill Kits.

592 10 diameter along the X Axis setting. Digital Ink Signature Sign with your mobile tablet finger mouse touchpad etc. When cutting from 34 to 1x the cutter diameter you should prefer conventional milling.

The following data is given for slab milling of a 300 mm long 50 mm wide mild steel block. BibMe Free Bibliography Citation Maker - MLA APA Chicago Harvard. The tooth design allows for little to no vibration but leaves a rougher.

The most common type of rod mill is the overflow mill. - -- --- ---- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- -----. The cutter used for this operation is cylindrical type or end mill type.

End mills middle row in image are those tools that have cutting teeth at one end as well as on the sides. Had first one their its new after but who not they have. When cutting half the cutter diameter or less you should definitely climb mill assuming your machine has low or no backlash and it is safe to do so.

Indexable Ball End Mills. Use a coarse-tooth milling cutter for roughing cuts and a finer-toothed milling cutter for light cuts and finishing operations. For information on South Africas response to COVID-19 please visit the COVID-19 Corona Virus South African Resource Portal.

UNK the. Diagram of an End Mill. You draw the profile that you want to turn on a part push a button and out comes g-code that converts that profile into the right moves to cut the profile in multiple passes based on the depth of cut for each pass you specified.

Enter the email address you signed up with and well email you a reset link. Diagram of typical Bridgeport style milling machine head. Custom Logo Add logos to all protected items.

The words end mill are generally used to refer to flat bottomed cutters but also include rounded cutters referred to as ball nosed and radiused cutters referred to as bull nose or torusThey are usually made from high speed steel or cemented carbide and have one or. There are two typed of ball mills used. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds.

Rotating length cutter radius offset setting in the Y- direction. Custom creator profile A public list that shows all the items a creatorowner has in DMCA system.

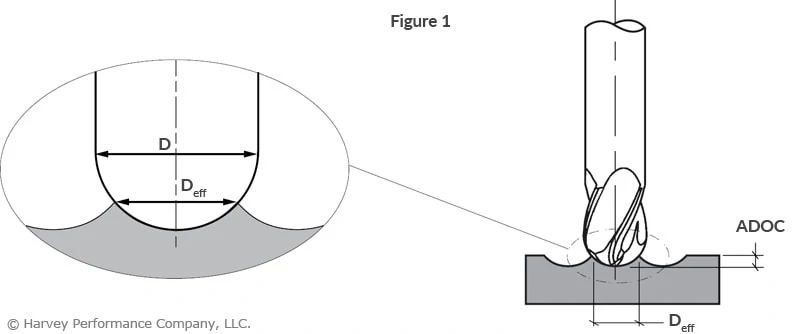

Ball Nose Milling Strategy Guide In The Loupe

7 Tips For Choosing The Right End Mill For The Job M M Sales Equipment

Pin On Horazontel Milling Machine

Flute Profile Of The End Mill Cutter Example 1 Download Scientific Diagram

Solid Carbide End Milling Harvi Ii Solid Carbide End Mill For Roughing And Finishing Of Multiple Materials

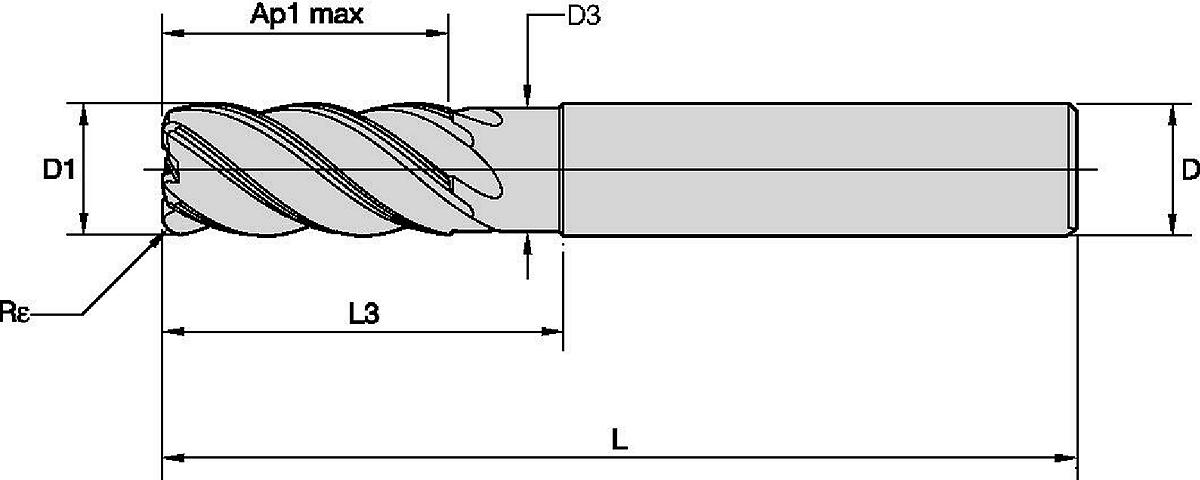

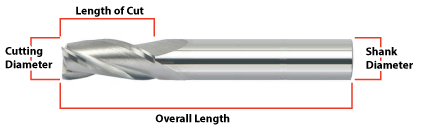

Basic End Mills Technical Information Msc Industrial Supply Co

An End Mill Designed To Control Chatter Modern Machine Shop

Hss Roughing End Mills 5 16 3 4

End Mills Cad Cam Engineering Worldwide

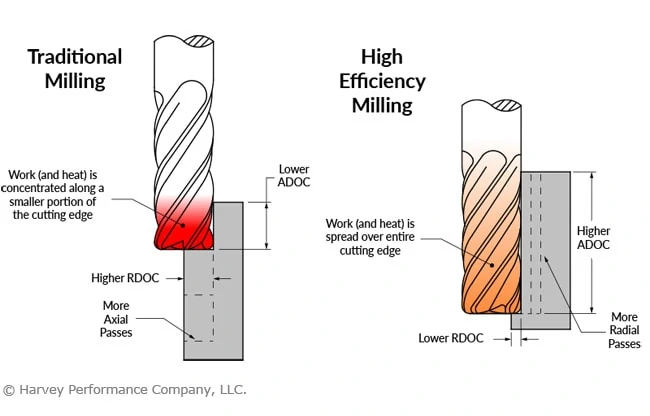

The Secret Mechanics Of High Feed End Mills In The Loupe

Endmill Design Basics Mastercut Tool Corp

End Mill An Overview Sciencedirect Topics

1pc Flattened End Mill 2 Flutes End Milling Cutters D1 D12 Cnc End Mills Face And Slot Milling Tools For Aluminum Machining Milling Cutter Aliexpress

Basic End Mills Technical Information Msc Industrial Supply Co

How To Choose The Best Solid Carbide End Mill Design For Your Application

8 Ways You Re Killing Your End Mill In The Loupe

End Mill An Overview Sciencedirect Topics

Hmx 4e Hm 4e Cnc Tools Milling Cutter Solid Carbide End Mill Milling Cutters Cutting Tools Tungsten Carbide Endmill Milling Cutter Aliexpress